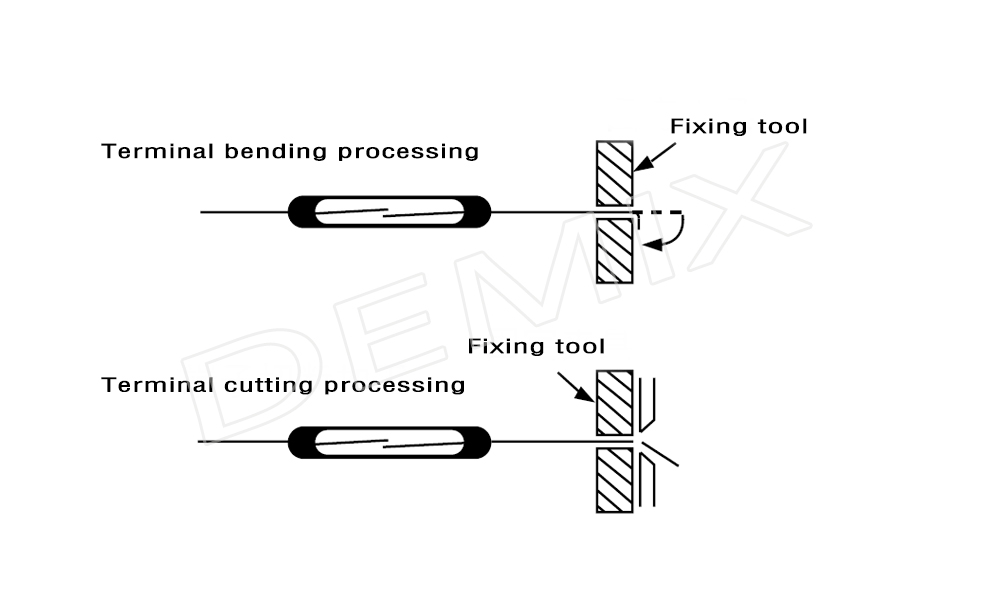

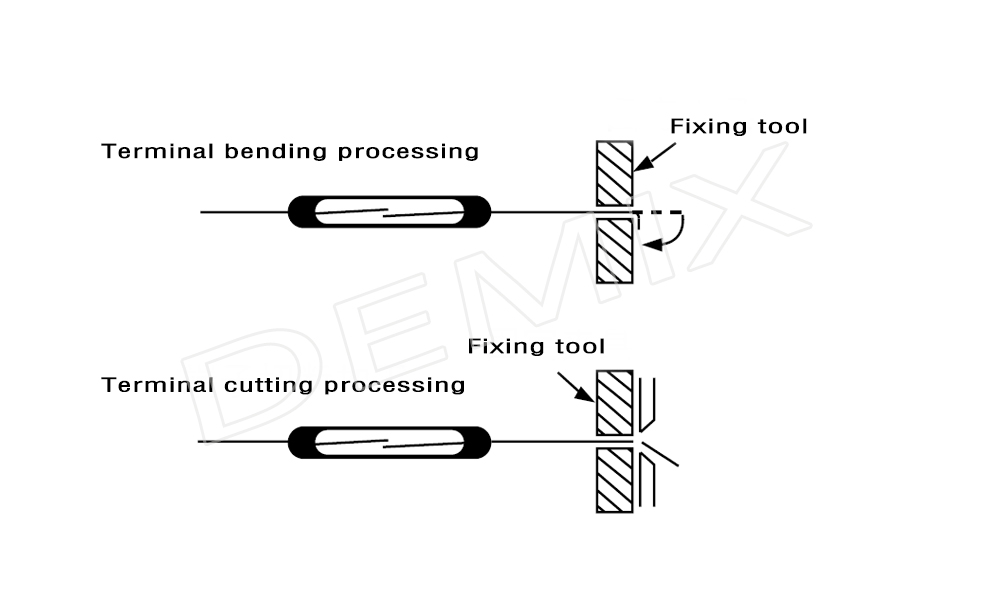

1. When using reed switches, they are rarely used directly. Generally, cutting and bending are carried out. Matters needing attention in these processes are as follows:

(1) The size of cutting or bending shall be calculated from the center of contact or the end of magnetic spring. If calculated from the end of the glass tube, the center position of the contact will change.

(2) During processing, in order to protect the sealing and bonding part, the magnetic spring terminal should be completely fixed before processing.

(3) After processing, it is necessary to confirm whether the glass tube is cracked or broken.

2. Cutting processing.

In the reed switch, the reed itself is also an integral part of the magnetic field circuit structure. When the reed terminal is cut off, the pull-in value and disconnection value will become higher. This is the case when measured by a standard coil. When driven by a permanent magnet, the change will be different due to the shape of the magnet and the direction of magnetization. Therefore, confirm the magnet used and the driving method.

3. Bending.

As with the cutting process, it is necessary to confirm the magnet used and the driving method.